Due to the increasing expectations of our Clients the machining department of Fémalk Zrt. is involved in increasingly more operations, up to creating finished products. More complex castings and stringent quality requirements make the continuous expansion of production equipment and technologies vital. We have introduced countless innovations in order to keep up with the competition and improve constantly and continue to do so. The following activities are carried out by our machining department:

- Assembly of threaded steel inserts

- Crimping

- Deburring (tumbling, shot blasting)

- CNC machining (milling, drilling, boring, threading, lathing)

- Special-purpose machining operations

- Helicoil insert assembly

- Heat treatment

We possess the following range of equipment for the machining, surface treatment, and cleaning of our products: 6 CNC lathes, 12 machining centres, 4 parts cleaning units, CNC drilling and threading machines, individual special-purpose machines, custom presses, shot blasting machines, tumbling machines.

Machining processes

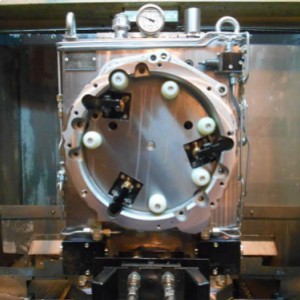

Our products are machined using custom equipment and chucks. In order to optimise our machining operations we have made custom machining tools. The execution or accuracy of operations is in many cases examined on machined parts using special-purpose test equipment.

Assembly and crimping processes

We are also increasingly performing assembly operations on our castings, such as crimping, assembling of threaded steel elements into castings, and assembling rubber and thread reinforcing inserts. During our assembly and crimping processes we strive to ensure a high level of operational safety; therefore we employ various control equipment (PokaYoke gates) to examine the conformity of operations.

Surface treatment processes

We treat the surface of our products according to the needs of our clients, using shot blasting, abrasive, and deburring operations. Our machine park includes both high-capacity linear shot blasting and tumbling units and hook-type shot blasting units with a lower capacity but capable of accepting larger items.

Prototype production

Fémalk Zrt. is also a partner in product development. Our machining department has played an active role in the development of several car and motorbike parts. We carry out prototype production in collaboration with the product development department, until the sample parts obtains its final shape.